No Backing

Embroidered badges can be made without a backing. (In fact, they start out that way.) These badges will show the twill or threads on the back of the badge, and they are generally more flexible. Badges without backings lack the thickness and stiffness of those with backing. However, they work best when you plan to sew them directly onto garments or other fabric items.

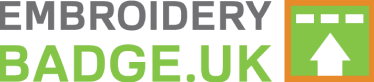

Plastic Backing

Heat Seal (Iron On) Backing

Heat-seal backing—often called iron-on—uses a heat-activated adhesive layer that bonds the badge securely to fabric when applied with an iron or heat press. And, it adds mild stiffness and keeps the badge flat during wear. At EmbroideryBadge.UK, we use a high-strength adhesive that lasts for 50–80 wash cycles. While this method is quick and clean, we recommend sewing a few stitches for additional hold, especially on water-resistant garments.

Temporary Sticker Backing (Adhesive Backing)

An adhesive backing offers a temporary attachment method and is best for single-use or event badges. The strong glue on the back sticks firmly to most fabrics but is not suitable for washing. After you remove the badge, the adhesive gradually loses strength; therefore, it works best for short-term use instead of permanent application.

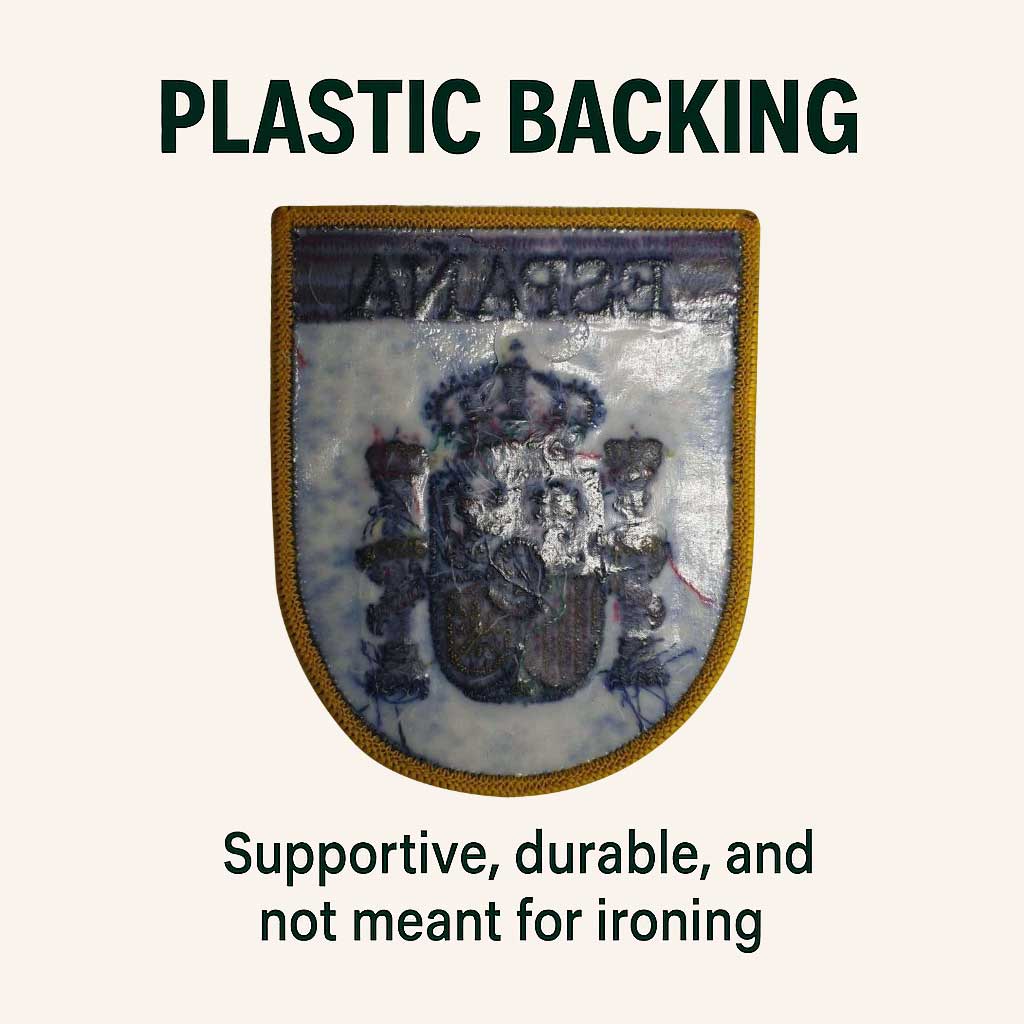

Hook-Sided Backing

This backing type is widely used for military, emergency service, and tactical uniforms. It allows badges to be attached and removed multiple times without damage. The hook side is stitched firmly to the badge, while the loop side is already sewn onto the garment. This option is available in several colours to match different uniforms.

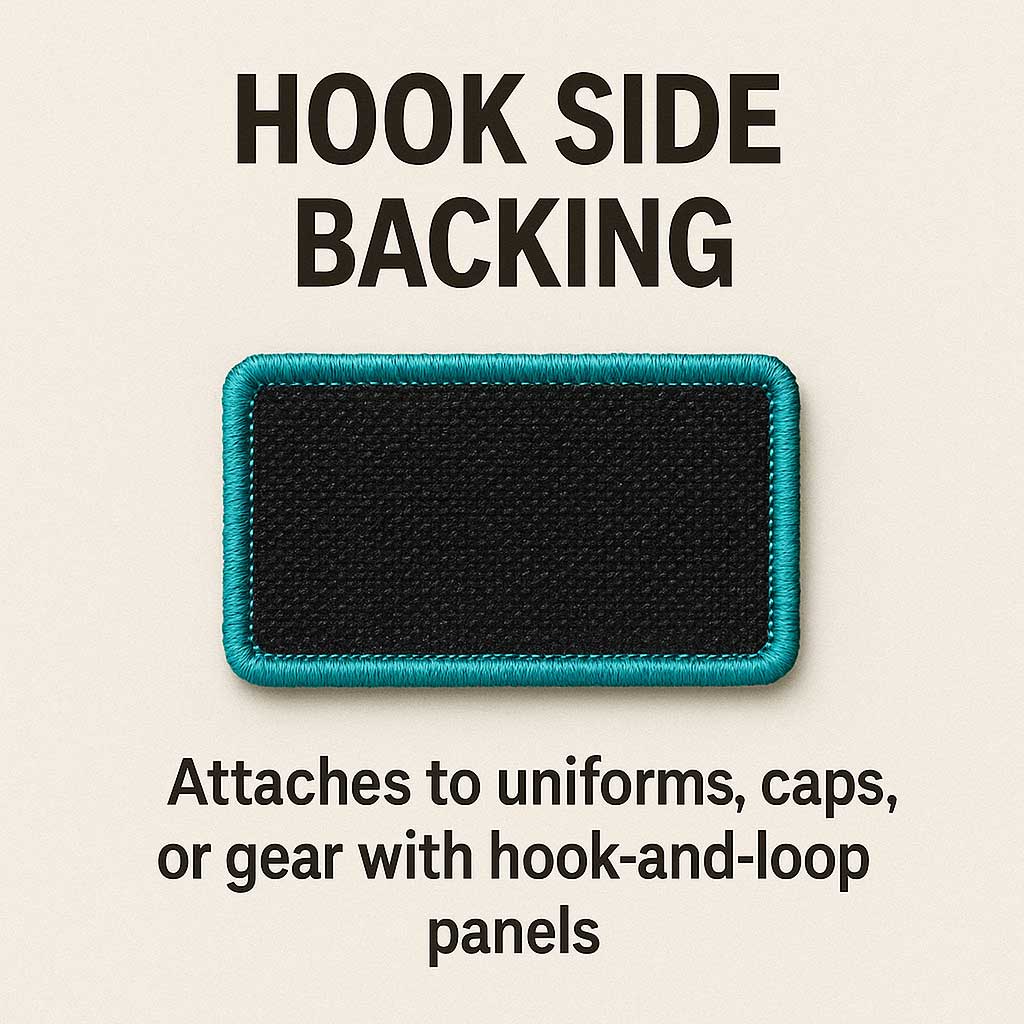

Hook + Loop Backing

The double-sided version includes both the hook and loop components, making it ideal when the garment has no existing fastener area. You stitch the loop part directly onto the garment, and the hook side connects firmly to the badge. This backing remains fully reusable and works well for heavy-duty applications where users frequently switch or reposition their patches.

Non Woven Backing

A non-woven backing provides light stiffness without making the badge rigid. It adds stability during embroidery and gives the reverse side a neat, finished appearance. So, this backing type is ideal for appliqué or hand-sewn badges, where flexibility and a clean edge are equally important.